Makita BHR162 Bedienungsanleitung

Stöbern Sie online oder laden Sie Bedienungsanleitung nach Rotationshämmer Makita BHR162 herunter. Repair - Makita Benutzerhandbuch

- Seite / 12

- Inhaltsverzeichnis

- LESEZEICHEN

- Specification 1

- Standard equipment 1

- Optional accessories 1

- ECHNICAL INFORMATION 1

- [1] NECESSARY REPAIRING TOOLS 2

- P 2 / 12 2

- [2] LUBRICATION 2

- Ring spring 19 3

- P 4 / 12 4

- [3] DISASSEMBLY/ASSEMBLY 4

- [3] -2. Armature 4

- P 5 / 12 5

- [3] -2. Armature (cont.) 5

- [3] -3. Gear Section 5

- P 6 / 12 6

- P 7 / 12 7

- [3] -3. Gear Section (cont.) 7

- P 8 / 12 8

- P 9 / 12 9

- [3] -5. Tool Holder Section 9

- [Correct] [Wrong] 10

- Circuit diagram 11

- Wiring diagram 12

Inhaltsverzeichnis

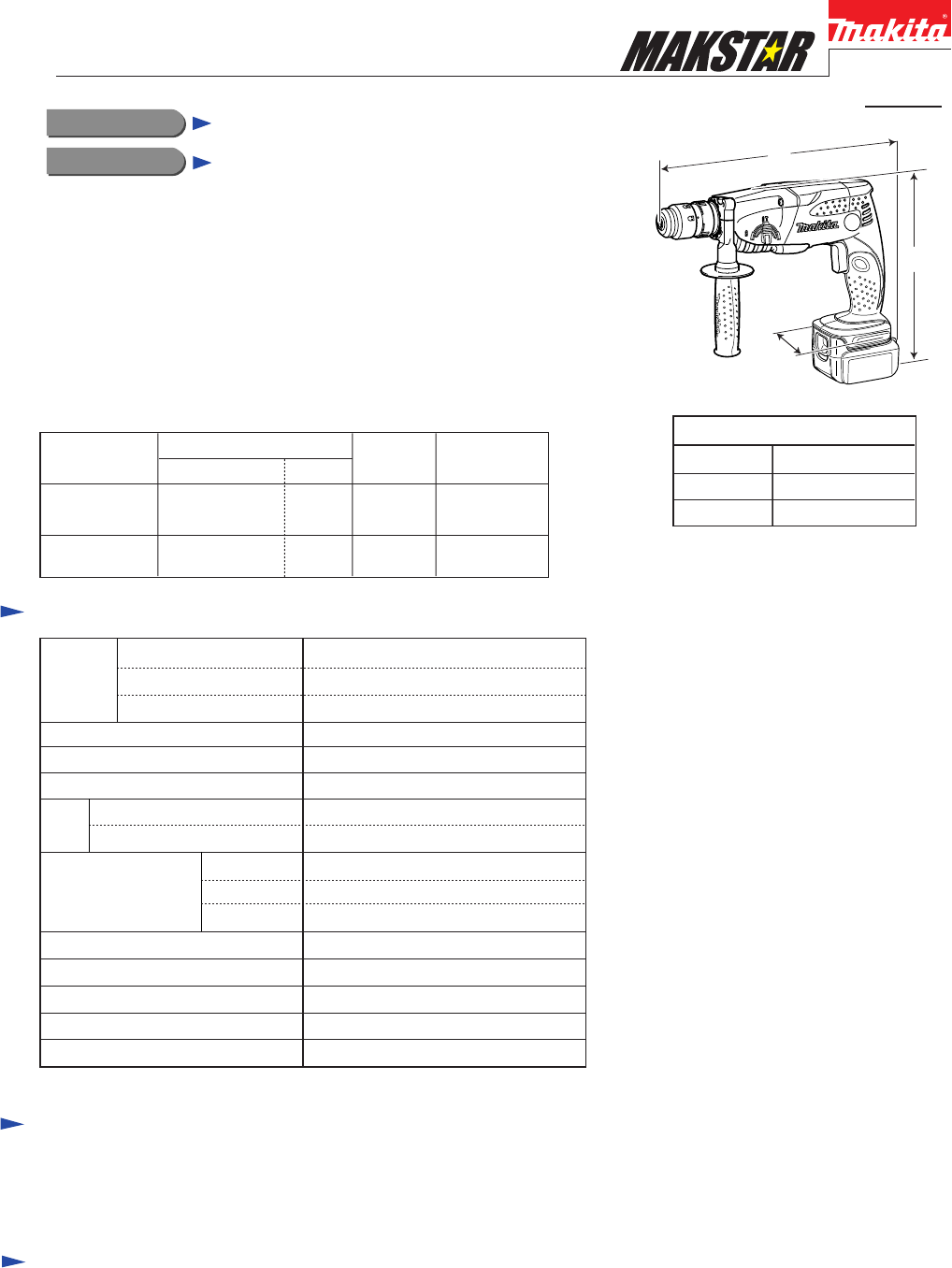

Model No. DescriptionPRODUCTCONCEPT AND MAIN APPLICATIONS P 1 / 12SpecificationStandard equipmentDimensions: mm (")Width (W)Height (H)Length (L)2

P 10/ 12Repair[3] DISASSEMBLY/ASSEMBLY1) Install X ring 13 on Impact bolt. Assemble Ring 11 to Impact bolt as illustrated to left in Fig. 33.2)

Circuit diagramP 11/ 12Color index of lead wires' sheathBlackRedOrangeBlueYellowYoke UnitFETEndbellSwitchLight CircuitConnectorTerminalFig. 38LED

Wiring diagramP 12/ 12Connectorlead wire holderlead wire holderlead wire holderLEDConnecting terminalribTerminal sideSwitch sideWith the lead wire (or

P 2 / 12Repair[2] LUBRICATIONApply the following kinds of grease to protect parts and product from unusual abrasion, when repairing or changing carbon

P 3 / 12Repair[3] DISASSEMBLY/ASSEMBLY[3] -1. Tool Holder Fig. 3Fig. 4DISASSEMBLINGCap 35Ring spring 191R003Ring 211) After taking off Cap 35, remove

P 4 / 12Repair[3] DISASSEMBLY/ASSEMBLY[3] -2. ArmatureFig. 7 Fig. 8Fig. 10 Fig. 11 Fig. 12DISASSEMBLINGLock buttonChange leverChange lever positioneda

P 5 / 12Repair[3] DISASSEMBLY/ASSEMBLY[3] -2. Armature (cont.)Do the reverse of the disassembling steps.ASSEMBLING[3] -3. Gear SectionFig. 13Fig. 14 F

P 6 / 12Repair[3] DISASSEMBLY/ASSEMBLY[3] -3. Gear SectionFig. 17Fig. 18 Fig. 20Fig. 19DISASSEMBLINGASSEMBLINGFig. 16 9) Remove Ball bearing 606ZZ fr

P 7 / 12Repair[3] DISASSEMBLY/ASSEMBLY[3] -3. Gear Section (cont.)ASSEMBLING7) Assemble Ball bearing 606ZZ, Oil seal 25 and Ball bearing 6805LLB to Ge

P 8 / 12Repair[3] DISASSEMBLY/ASSEMBLY[3] -4. Inner Housing CompleteFig. 23 Fig. 24 Fig. 25DISASSEMBLINGCompression spring 3Change plateStopper plateP

P 9 / 12Repair[3] DISASSEMBLY/ASSEMBLY[3] -4. Inner Housing Complete (cont.)Fig. 27 Fig. 282) Mount Compression spring 3 in place by connecting one en

Weitere Dokumente für Rotationshämmer Makita BHR162

(23 Seiten)

(23 Seiten) (8 Seiten)

(8 Seiten)

Kommentare zu diesen Handbüchern